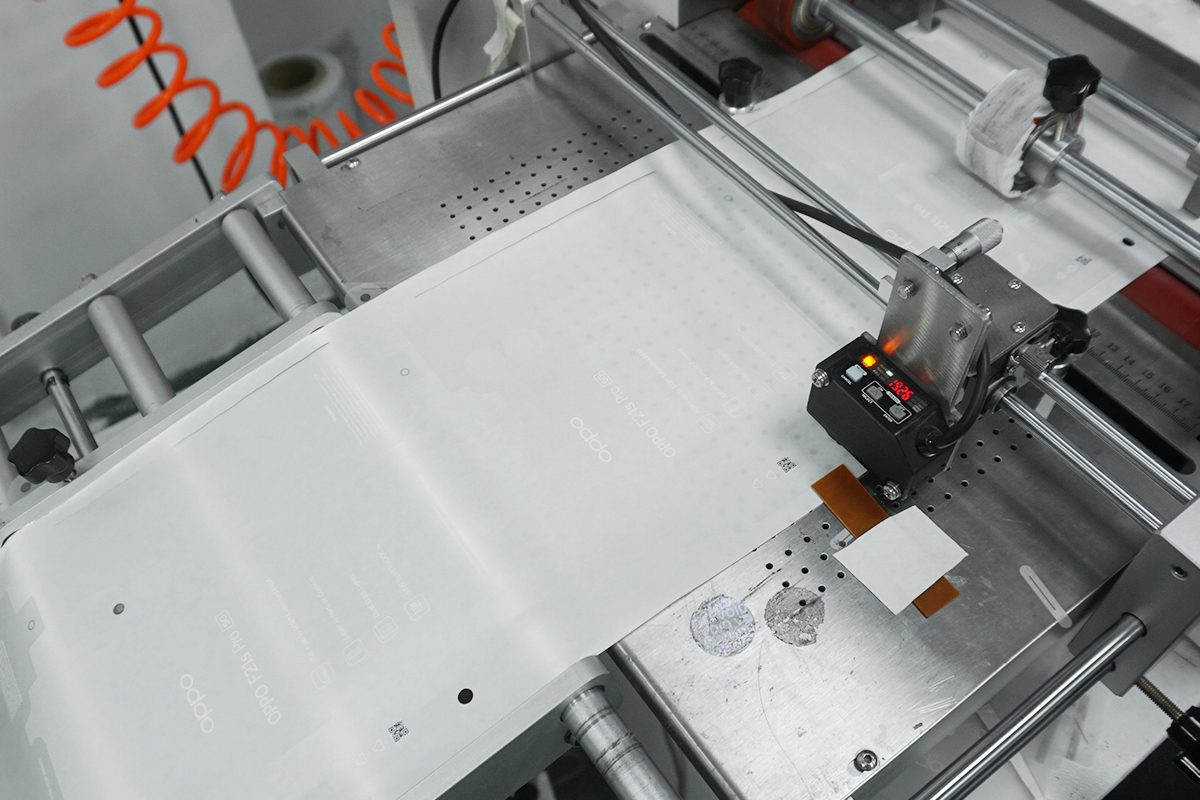

BOPP Label Material: Unveiling the Versatile World of Biaxially Oriented Polypropylene

In the realm of labeling and packaging, the term BOPP, or Biaxially Oriented Polypropylene, stands out as a versatile and widely used material. BOPP label material has gained prominence for its unique properties and broad applications across various industries. In this article, we will delve into the intricacies of BOPP label material, exploring its characteristics, applications, and the parameters that make it an indispensable choice.

Understanding BOPP Label Material

Biaxially Oriented Polypropylene (BOPP):

BOPP is a type of polypropylene film that undergoes a biaxial orientation process. This process involves stretching the film in both the machine and transverse directions, imparting enhanced strength, clarity, and dimensional stability to the material. BOPP films are widely appreciated for their high tensile strength, excellent printability, and resistance to moisture.

Characteristics of BOPP Label Material

Clarity and Transparency:

BOPP label material boasts exceptional clarity and transparency, allowing for vivid and sharp printing. This feature makes it ideal for applications where product visibility and aesthetic appeal are paramount.

High Tensile Strength:

The biaxial orientation process significantly increases the tensile strength of BOPP. This property ensures that labels made from BOPP can withstand the rigors of handling, shipping, and storage without compromising their structural integrity.

Printability:

BOPP labels provide an excellent surface for high-quality printing. The material readily accepts various printing techniques, including flexography, gravure, offset, and digital printing. This makes BOPP labels suitable for a wide range of applications.

Resistance to Moisture:

BOPP exhibits low moisture absorption, making it a preferred choice for labels that need to maintain their integrity in humid conditions. This feature is particularly crucial in industries such as food and beverage, where moisture resistance is essential.

The Power of Precision: Crafting with Hotmelt, Removable, and Acrylic Glues

Chemical Resistance:

BOPP label material demonstrates resistance to a variety of chemicals, enhancing its suitability for applications where exposure to chemicals is a concern. This characteristic contributes to the durability of labels in challenging environments.

Applications of BOPP Label Material:

Food and Beverage Packaging:

BOPP labels find extensive use in the food and beverage industry for labeling products such as bottles, jars, and food packaging. The material's clarity allows for attractive and informative labeling, enhancing product presentation on store shelves.

Personal Care and Cosmetics:

BOPP labels are favored in the personal care and cosmetics industry for their print quality and the ability to create aesthetically pleasing labels for skincare products, cosmetics, and toiletries.

Pharmaceutical Labels:

In the pharmaceutical sector, where stringent labeling requirements exist, BOPP labels offer a combination of durability and printability. They are used for labeling medicine bottles, blister packs, and other pharmaceutical packaging.

Industrial Labels:

BOPP label material is well-suited for industrial applications, including labeling durable goods, machinery, and chemical products. Its resistance to moisture and chemicals ensures that labels remain legible and intact in demanding environments.

Promotional Labels:

BOPP labels are popular for promotional labeling due to their vibrant printing capabilities. This includes labels for promotional products, limited-edition items, and event marketing.

Parameters and Specifications:

Thickness:

BOPP label material is available in various thicknesses, typically measured in microns (μm) or mils (thousandths of an inch). Common thickness ranges include 20μm to 50μm, depending on the specific application.

Adhesive Type:

BOPP labels can feature different types of adhesives, including permanent, removable, and repositionable options. The choice of adhesive depends on the intended use of the label.

Finish:

BOPP labels come in various finishes, including glossy, matte, and clear. The finish can impact the visual appeal of the label and may be chosen based on design preferences and application requirements.

Printing Compatibility:

BOPP label material is compatible with various printing technologies, including flexography, gravure, offset, and digital printing. Printers can select the printing method that best suits their production processes and requirements.

Temperature Resistance:

BOPP labels may exhibit varying levels of temperature resistance. This parameter is crucial for applications where labels may be exposed to extreme temperatures during transportation, storage, or use.

BOPP label material stands as a testament to the innovation and versatility in the field of packaging and labeling. Its unique combination of clarity, strength, and printability makes it an ideal choice for a myriad of applications across different industries. Whether enhancing the visual appeal of consumer products or meeting the stringent requirements of pharmaceutical labeling, BOPP label material continues to play a pivotal role in modern packaging solutions. As technology advances, and consumer demands evolve, the adaptability of BOPP labels ensures they will remain a staple in the world of product labeling for years to come.

#Direct thermal label raw material# #Label paper raw material# #Label stock raw material#

#Barcode adhesive label raw material# #Barcode shipping label roll raw material#

#Cheap price hot melt jumbo label roll raw material# #Label raw material pvc shrink film roll#

#Producing raw material label jumbo roll# #Raw material label roll# #Raw material of label#

#Self-adhesive label film raw material# #Semi gloss paper label raw material# #Shipping label roll raw material# #Yellow liner thermal label roll raw material#

Post time: Dec-22-2023